Painting diecast aluminum can transform old toys, models, or automotive parts, giving them a fresh, new look. Achieving a perfect finish, however, requires understanding the unique challenges of this material and following the proper steps. This comprehensive guide will walk you through the entire process, from surface preparation to the final clear coat, ensuring your painting projects are successful and long-lasting. With the right approach, you can achieve professional-looking results at home, revitalizing your diecast aluminum pieces.

Understanding Diecast Aluminum and its Challenges

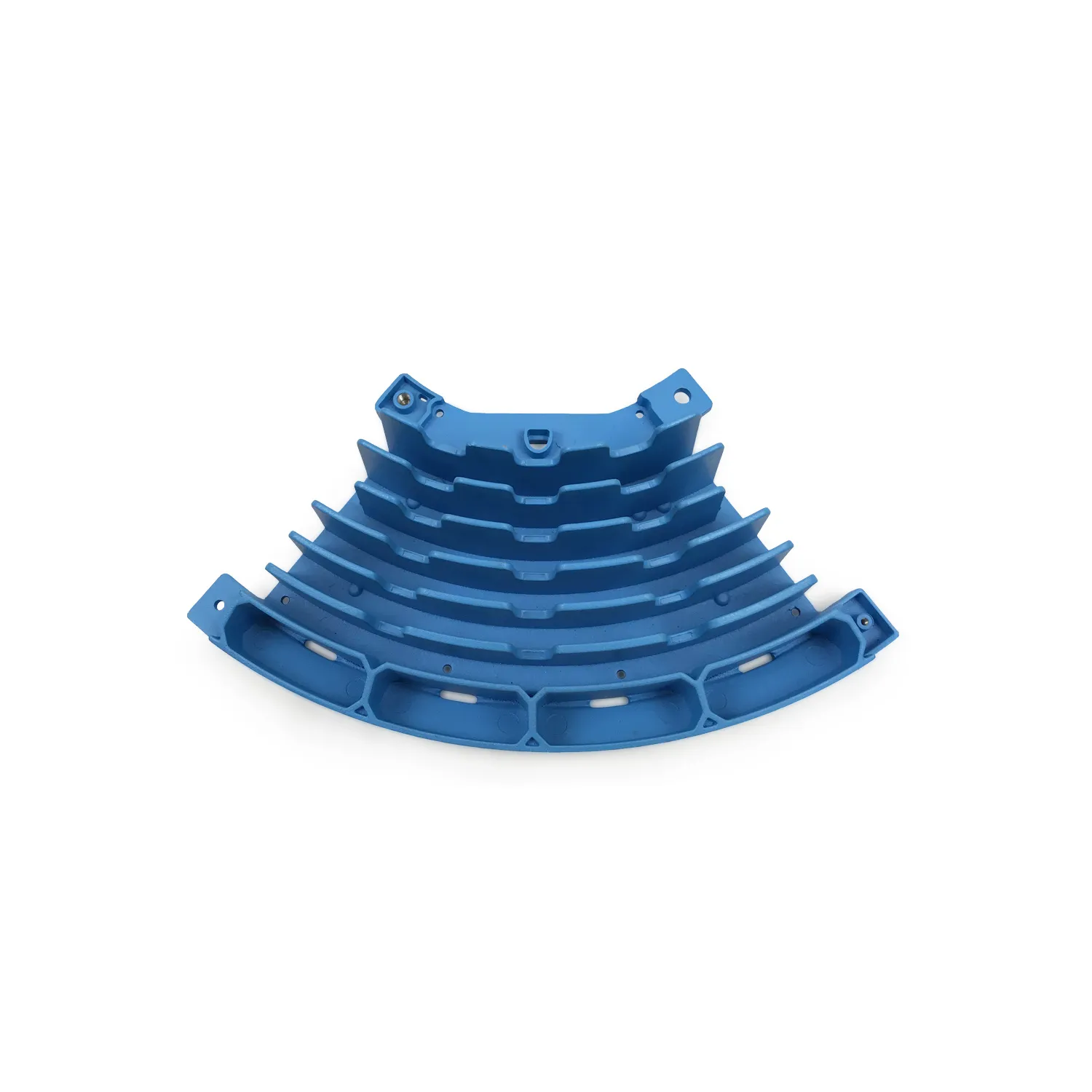

Diecast aluminum is a metal alloy created by injecting molten aluminum under high pressure into a mold. This process creates intricate shapes with high accuracy, making it popular for various applications, from toy cars and model airplanes to automotive parts and even some industrial components. Its lightweight nature and ability to be molded into complex designs contribute to its widespread use. However, the very properties that make diecast aluminum desirable also present challenges when it comes to painting.

What is Diecast Aluminum?

Diecast aluminum is a specific type of aluminum alloy produced using a high-pressure die-casting process. This process forces molten aluminum into a mold, creating intricate shapes and designs with high precision. Diecast aluminum is favored for its lightweight properties, durability, and its ability to replicate complex designs. It is found in a wide array of products, including toys, model cars, automotive parts, and other consumer and industrial items. The casting process imparts unique characteristics to the metal, influencing how paint adheres and how the surface must be prepared before applying any coating.

Challenges of Painting Diecast Aluminum

The porous nature of diecast aluminum and the presence of mold release agents are key challenges in the painting process. These factors can hinder paint adhesion, leading to issues like peeling, blistering, and an uneven finish. Diecast aluminum can also be prone to corrosion if not properly prepared and protected. Understanding these challenges is crucial for choosing the correct paints, primers, and application techniques to ensure a durable and aesthetically pleasing paint job. Ignoring these factors can result in a paint job that is easily damaged and detracts from the piece’s appearance.

Surface Preparation is Key

Effective surface preparation is the most critical step in painting diecast aluminum. It ensures that the paint adheres properly and provides a smooth, even finish. Proper preparation involves cleaning, removing old paint and debris, and creating a slightly roughened surface for the primer to grip. Neglecting this step will almost certainly lead to paint failure down the line. The goal is to create a clean, slightly etched surface that promotes adhesion and extends the lifespan of your paint job.

Cleaning the Diecast Aluminum

Before painting, the diecast aluminum surface must be thoroughly cleaned to remove any dirt, grease, oil, or other contaminants. Use a degreasing cleaner or a mild soap solution and warm water. Scrub the surface gently with a soft brush or cloth. Rinse the part thoroughly with clean water and allow it to dry completely. Ensuring a clean surface is vital for the primer to adhere properly. Any residue left on the surface can prevent the paint from bonding correctly, leading to peeling or other imperfections.

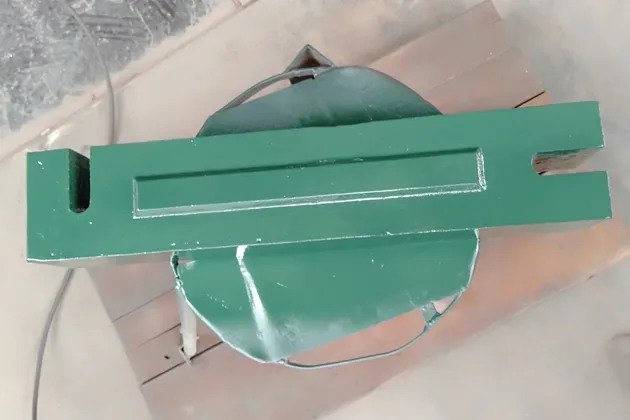

Removing Old Paint and Debris

If the diecast aluminum has old paint or any debris, it needs to be removed. You can use paint strippers specifically designed for metal surfaces, carefully following the manufacturer’s instructions. Alternatively, gentle abrasive methods like bead blasting or using fine-grit sandpaper can be used, but care should be taken not to damage the underlying metal. Be sure to wear appropriate safety gear, including gloves, eye protection, and a respirator. Thoroughly removing any remnants of the old paint is important for achieving a smooth surface.

Sanding and Smoothing the Surface

Once clean, the surface should be lightly sanded with fine-grit sandpaper (220-grit or higher). This process creates a slightly roughened surface that enhances primer adhesion. Sand in a consistent pattern, ensuring the entire surface is evenly treated. After sanding, remove any sanding dust with a tack cloth or compressed air. The goal is to create a slightly textured surface, allowing the primer to bond effectively. Avoid over-sanding, which can damage the diecast aluminum.

Choosing the Right Primer

The primer is the foundation of a successful paint job. It provides a crucial bonding layer between the diecast aluminum and the topcoat. Selecting the right primer is as important as the surface preparation. It not only promotes adhesion but also helps to seal the porous surface of the diecast aluminum, preventing moisture and corrosion. Furthermore, some primers provide additional benefits, like filling minor imperfections and enhancing the durability of the finish.

Types of Primers for Diecast Aluminum

Several types of primers are suitable for diecast aluminum. Etching primers chemically etch the surface to promote adhesion, making them ideal for difficult-to-paint metals. Epoxy primers offer excellent durability and corrosion resistance, forming a tough barrier against the elements. Self-etching primers combine etching and priming properties, simplifying the preparation process. The best choice depends on the specific project and the desired level of protection. Always select a primer compatible with the topcoat you intend to use.

Applying the Primer Correctly

Apply the primer in thin, even coats, following the manufacturer’s instructions. Avoid applying too much primer at once, as this can lead to runs and drips. Allow each coat to dry completely before applying the next. Using multiple thin coats is preferable to a single thick coat. Once the primer is fully dry, lightly sand it with fine-grit sandpaper to remove any imperfections. This creates a perfectly smooth surface for the topcoat, guaranteeing an even finish. Proper primer application sets the stage for a professional-looking paint job.

Selecting the Best Paint

Choosing the right paint is the next crucial step. The paint you select will determine the final look, durability, and resistance of your painted diecast aluminum project. The type of paint, color, and finish should align with your project goals. Consider factors like the environment, the desired level of protection, and the overall aesthetic to help you select the most suitable paint for your diecast aluminum project.

Types of Paints for Diecast Aluminum

Several paint types are suitable for diecast aluminum. Acrylic lacquers dry quickly and provide a smooth finish, making them popular for model and hobby applications. Enamel paints offer good durability and are available in various colors and finishes. Urethane paints are highly durable and resistant to chemicals, making them suitable for automotive parts and other demanding applications. The choice of paint depends on the project requirements, but it’s essential to use a paint compatible with the primer. Consider the location and use of the painted object when selecting a paint.

Paint Application Techniques

Proper paint application is vital for a flawless finish. Use a spray gun or aerosol can, holding it at a consistent distance from the surface. Apply multiple thin coats, allowing each coat to dry completely before applying the next. Avoid applying thick coats, as they can lead to runs and drips. Maintain a consistent spray pattern, overlapping each pass slightly. The environment also plays a role; paint in a well-ventilated area, free from dust and extreme temperatures. Following these steps will help you achieve a professional-looking paint job.

Achieving a Flawless Finish

The key to achieving a flawless finish on diecast aluminum lies in the details. Using the correct techniques and taking your time during the application process will ensure a professional result. Patience and attention to detail are crucial. Don’t rush the process; each step contributes to the final appearance of the painted surface. A perfect paint job is both beautiful and durable.

Multiple Thin Coats are Essential

Instead of attempting to apply a single thick coat, use multiple thin coats of paint. This technique reduces the risk of runs, drips, and unevenness. Allow each coat to dry completely before applying the next. Building up the color gradually ensures an even and durable finish. Thin coats also allow for better control, minimizing the potential for errors. This approach is the most effective way to achieve a professional-looking result.

Drying and Curing

Drying and curing are important steps in the painting process. Allow the paint to dry completely according to the manufacturer’s instructions. This typically involves allowing the painted piece to sit in a clean, dust-free environment. The drying time varies depending on the type of paint, the temperature, and the humidity. Some paints require curing, a process that involves exposing the painted part to heat, which further hardens the paint and improves its durability. Refer to the paint manufacturer’s guidelines for specific drying and curing times. Proper curing ensures the paint’s long-term performance.

Addressing Common Painting Issues

Even with careful preparation and application, painting challenges can occur. Learning how to identify and address common issues can help you rectify problems and achieve a perfect finish. Problems such as runs, drips, and peeling are often the result of issues such as improper preparation, incorrect application, or environmental factors. Knowledge and quick action are essential when dealing with painting issues.

Runs, Drips, and Unevenness

Runs and drips often occur when too much paint is applied at once. To fix this, allow the paint to dry completely, then carefully sand down the imperfections with fine-grit sandpaper. Feather the edges of the sanded area, then reapply the paint in thin coats. Unevenness can be caused by improper application or poor surface preparation. Make sure to maintain a consistent distance and spray pattern. Address unevenness by sanding the affected areas and applying additional thin coats until the finish is smooth. Patience and care will resolve these issues.

Peeling and Blistering

Peeling and blistering are usually caused by poor surface preparation, incompatible primers or paints, or moisture. If peeling or blistering occurs, remove the paint completely, and re-prepare the surface. Choose a compatible primer and paint system. Ensure the surface is clean and dry before priming and painting. Allow the paint to dry and cure properly. Prevention is key; proper preparation and following the product instructions are your best defense against these paint failures. Addressing these issues promptly saves time and ensures the longevity of your paint job.

Final Touches and Protection

Once the paint has dried and cured, the final touches enhance the finish and provide additional protection. These steps are essential for achieving a professional appearance and extending the lifespan of your paint job. Completing these steps will add beauty and durability to your finished piece.

Clear Coats and Sealants

Applying a clear coat is a great way to protect the paint and enhance the finish. Clear coats add gloss, protect against UV rays, and provide an extra layer of protection against scratches and abrasion. Choose a clear coat that is compatible with your paint type. Apply the clear coat in thin, even coats, allowing each coat to dry completely before applying the next. For maximum protection and shine, a clear coat is a must-have step. This final layer protects the color and contributes to the overall aesthetics.

Long-Term Maintenance

To maintain the finish of your painted diecast aluminum project, regularly clean it with a mild soap and water solution. Avoid using harsh chemicals or abrasive cleaners. Protect the painted surface from direct sunlight and extreme temperatures. If scratches or chips occur, touch them up promptly to prevent further damage. Proper maintenance will help to preserve the appearance and extend the lifespan of your paint job. These efforts will ensure your painted items remain beautiful for years to come.

Painting diecast aluminum is a rewarding project that can transform old items into new, beautiful pieces. By following these steps, you can achieve a professional-looking finish. Remember, surface preparation, choosing the right products, and using proper techniques are crucial to success. Enjoy the process, and don’t be afraid to experiment and learn as you go. With patience and attention to detail, you can achieve stunning results. So, get started, and bring new life to your diecast aluminum projects.