Understanding Diecast Car Painting

Diecast car painting is a rewarding hobby that allows enthusiasts to customize and restore their miniature vehicles. Whether you are looking to refresh an old model, create a unique design, or simply enjoy the process of bringing a diecast car back to its former glory, understanding the fundamentals of painting is key. This guide will walk you through the entire process, from initial preparation to the final clear coat, ensuring a professional-looking finish. Successful diecast car painting requires patience, attention to detail, and the right techniques. This comprehensive guide will provide you with the knowledge and skills needed to transform your diecast cars into stunning works of art. From selecting the appropriate paints to mastering the application techniques, you’ll learn how to avoid common pitfalls and achieve a flawless finish.

Types of Diecast Car Paints

Choosing the right paint is crucial for achieving a high-quality finish on your diecast cars. Different types of paints have varying properties, advantages, and disadvantages. Understanding these differences will help you select the best option for your project. The selection should consider the paint’s durability, ease of application, and the final look you are trying to achieve. Each type of paint has its own set of benefits and drawbacks, so carefully consider your options to ensure the best possible outcome for your diecast car painting project.

Acrylic Paints

Acrylic paints are water-based, making them easy to clean up and safe to use. They dry quickly and are available in a wide range of colors. Acrylics are a great choice for beginners due to their forgiving nature. They are less likely to run or sag compared to other paints. They also provide good coverage and are relatively easy to apply. However, acrylics might not be as durable as enamel or lacquer paints, and they can be susceptible to scratches. They are ideal for detail work and are a good starting point for those new to the hobby. With proper preparation and sealing, acrylics can produce excellent results.

Enamel Paints

Enamel paints offer excellent durability and a smooth, glossy finish. They are oil-based and take longer to dry, which can be both an advantage and a disadvantage. The extended drying time allows for more time to correct mistakes, but it also means the project takes longer to complete. Enamels provide superior resistance to chipping and wear, making them ideal for models that will be handled frequently. They typically require the use of solvents for thinning and cleaning, so proper ventilation is essential. The glossy finish achieved with enamels often requires minimal polishing, resulting in a professional appearance.

Lacquer Paints

Lacquer paints dry very quickly and provide a hard, durable finish. They are known for their excellent gloss and are often used in professional diecast car painting. Lacquers require the use of solvents and good ventilation, and they can be more challenging to apply than acrylics or enamels. Because they dry so rapidly, it’s important to work quickly and efficiently to avoid imperfections. Lacquers are known for their ability to create a high-gloss finish. This requires careful surface preparation and proper application techniques. The quick drying time allows for rapid project completion. They are a favorite among experienced modelers due to their professional-grade results.

Essential Tools and Supplies

Having the right tools and supplies is essential for a successful diecast car painting project. Investing in quality tools will not only make the process easier but also improve the final result. From basic cleaning supplies to advanced painting equipment, gathering the necessary items is the first step. A well-equipped workspace, proper preparation and application of the paint, and attention to detail are all crucial for a professional outcome.

- Diecast cars

- Paint (Acrylic, Enamel, or Lacquer)

- Primer

- Airbrush or spray cans

- Paint thinner or solvent

- Masking tape and putty

- Sandpaper (various grits)

- Detailing brushes

- Clear coat

- Polishing compound and cloths

Preparing Your Diecast Car

Proper preparation is the most critical step in diecast car painting, as it directly impacts the final appearance and durability of the paint. Taking the time to carefully prepare your model will ensure a smooth, even finish and prevent common issues like paint peeling or bubbling. This process includes disassembly, cleaning, surface preparation, and priming. Neglecting any of these steps can lead to significant problems, so meticulous attention to detail is key. Before you even think about applying paint, you need to dedicate time to getting the surface just right for the paint to properly adhere to.

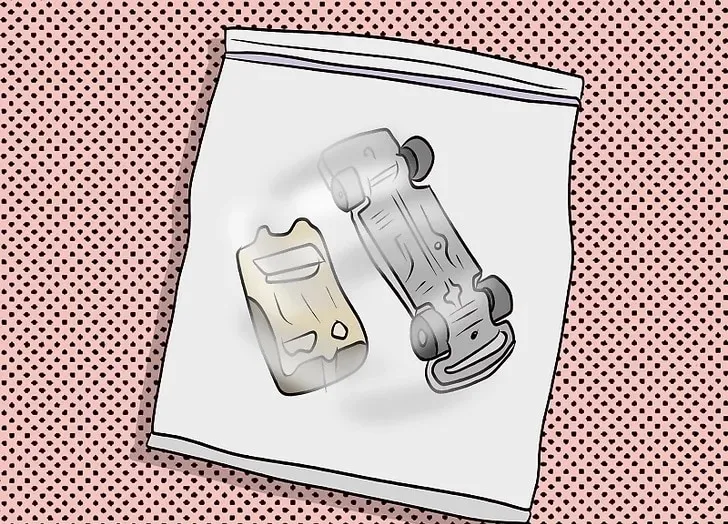

Disassembly and Cleaning

Before painting, disassemble the diecast car as much as possible. This will allow you to paint each part individually and achieve a more professional result. Carefully remove any screws, clips, and other components. Clean all parts thoroughly with soapy water or a degreaser to remove any dirt, oils, or old paint. Ensure that all surfaces are completely dry before moving to the next step. This meticulous approach ensures that the paint adheres correctly and avoids imperfections, leading to a flawless final finish. Properly cleaning the model is essential for the paint to properly adhere and prevent defects.

Surface Preparation

Once the car is clean, inspect the surface for any imperfections, such as scratches, dents, or raised areas. Use sandpaper of varying grits to smooth out these imperfections. Start with a coarser grit and gradually move to a finer grit for a smooth surface. Sanding helps the primer and paint adhere better. It also creates a uniform surface that prevents paint from bubbling or cracking. When sanding, apply even pressure and work in a consistent motion. It’s a good idea to use a tack cloth to remove any sanding dust. Preparing the surface correctly is crucial for ensuring the paint adheres properly and achieves a smooth, professional finish. (Image of sanding diecast car)

Priming Your Diecast Car

Priming is essential for creating a uniform surface for the paint to adhere to. It also helps the paint to adhere properly and improves its durability. Apply a thin, even coat of primer to all surfaces of the car. Several thin coats are better than one thick coat to avoid runs or drips. Allow the primer to dry completely according to the manufacturer’s instructions. After the primer has dried, lightly sand the surface with fine-grit sandpaper to smooth out any imperfections. Priming is a critical step because it not only creates a base for the paint but also helps to identify and correct any remaining surface imperfections before applying the color coat. (Image of priming a diecast car)

Applying the Base Coat

Once the primer is dry, it is time to apply the base coat. The base coat is the main color you want your diecast car to be. Proper application techniques and choosing the appropriate method can make a big difference. You have a couple of options, either by using an airbrush or a spray can. When the paint is applied correctly and in thin, even layers, you will get the best results.

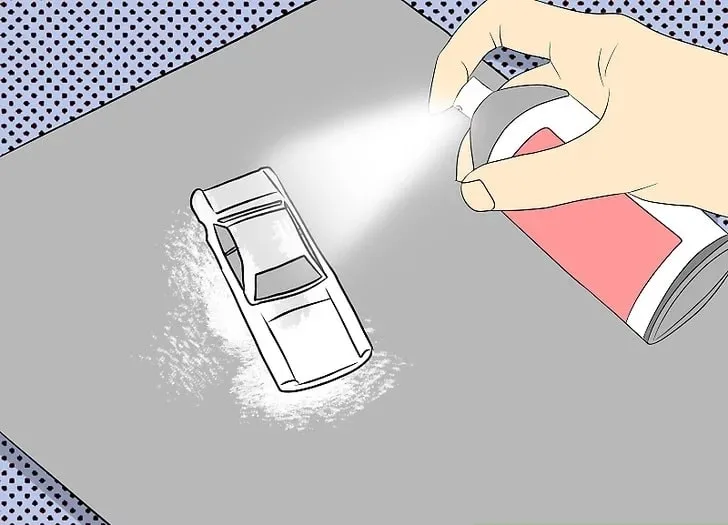

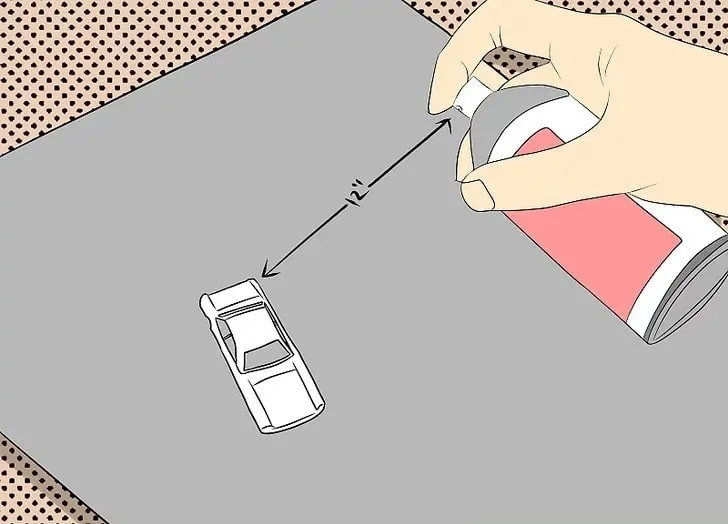

Using an Airbrush or Spray Can

Using an airbrush gives you the most control over the paint application, allowing for precise control over the paint flow and coverage. Airbrushes are ideal for achieving smooth, even coats and for intricate detailing. If you don’t have an airbrush, spray cans can also be used, especially for larger areas. Make sure you hold the can at the correct distance from the model and apply the paint in even strokes. The key to both methods is to apply multiple thin coats rather than one thick coat. This reduces the risk of runs, drips, and other imperfections. Always work in a well-ventilated area and wear a respirator to protect yourself from fumes. Using the correct equipment is key to an even paint job. (Image of using an airbrush on a diecast car)

Multiple Thin Coats

The most important rule for applying the base coat is to use multiple thin coats. Apply the first coat lightly, just enough to cover the surface. Let it dry according to the paint manufacturer’s instructions. Then, apply a second coat, and possibly a third, until the desired color and coverage are achieved. This method helps prevent runs and drips and ensures a smooth, even finish. Each coat should be allowed to dry completely before the next coat is applied. Patience is key when applying multiple thin coats, as it prevents imperfections and promotes a professional-looking finish. By building up the color gradually, you achieve better coverage and a more durable paint job.

Adding Details and Decals

Once the base coat is dry, you can start adding details and decals to your diecast car. This is where you can really make your model unique and personalized. The details can really bring the model to life, and the decals can make it resemble a real car.

Decal Application

Decals add realistic details to your model. Carefully cut out the decals you want to use, and soak them in water until they release from the backing paper. Position the decals on the model and gently dab them with a soft cloth to remove any air bubbles. Decal setting solutions can help the decals conform to the surface of the model and improve their adhesion. After the decals are dry, apply a clear coat to seal them and protect them from damage. By properly applying decals, you enhance the realism and overall appearance of your diecast car. (Image of applying a decal on a diecast car)

Detail Painting

Detail painting involves adding small details like stripes, logos, or trim. This can be done using fine-tipped brushes and detail paints. Use masking tape to protect areas you don’t want to paint. Steady hands and patience are essential for this process. Once the detail work is complete, allow the paint to dry completely before applying the clear coat. Precise detail painting enhances the overall realism and complexity of your model, transforming it into a true work of art.

Clear Coating and Finishing

The clear coat protects the paint job and gives it a glossy finish. Clear coating is the final step in the painting process, and it protects the paint and gives the model a finished look. Choosing the right clear coat, applying it correctly, and polishing the final finish are essential to producing a professional-looking model.

Choosing the Right Clear Coat

There are different types of clear coats, including acrylic and lacquer. Acrylic clear coats are easier to apply and clean up. Lacquer clear coats offer a harder, more durable finish. Consider the type of paint you used for the base coat when choosing a clear coat. Always read the manufacturer’s instructions to ensure compatibility. Choosing the right clear coat for your project helps protect the paint job and enhances the model’s appearance. (Image of clear coating a diecast car)

Polishing and Final Touches

After the clear coat has dried, you can polish the model to remove any imperfections and achieve a smooth, glossy finish. Use polishing compounds of different grades to remove any minor imperfections and enhance the shine. Apply the polishing compound with a soft cloth and rub in a circular motion. Once the polishing is complete, assemble all the components of the diecast car. By paying attention to these final touches, you will transform your diecast car from a painted model to a work of art. (Image of polishing a diecast car)

Troubleshooting Common Issues

Even with careful preparation and application, you might encounter some common issues during diecast car painting. Understanding these issues and how to fix them will help you achieve better results. Some of the common issues include paint runs and drips, and dust and debris. With a little practice, you can resolve any issues.

Paint Runs and Drips

Paint runs and drips occur when too much paint is applied at once. To avoid this, always apply thin coats and let each coat dry completely before applying the next. If you do get a run or drip, let the paint dry completely and carefully sand it down. Then, reapply the paint in thin coats. The goal is to gradually build up the paint layers, preventing the build-up that causes runs or drips. Proper technique and patience will prevent these problems.

Dust and Debris

Dust and debris can contaminate the paint surface, resulting in small bumps or imperfections. Always work in a clean, dust-free environment. Before painting, wipe down the model with a tack cloth to remove any dust particles. If you notice dust or debris in the paint, let the paint dry completely and gently sand the area with fine-grit sandpaper. Reapply the paint in thin coats. By maintaining a clean workspace and using proper preparation techniques, you can significantly reduce the chances of these imperfections. Proper preparation and a clean environment are critical for avoiding dust and debris.

Professional Diecast Car Painting Services

If you’re not confident in your ability to paint a diecast car or if you want a professional-quality finish, consider using a professional diecast car painting service. These services have the expertise, tools, and experience to deliver exceptional results. They can handle complex paint schemes, custom designs, and restorations. They will offer services that range from basic repainting to complete custom builds. Using a professional service can save you time and effort, and ensure a flawless finish. If you are looking for professional results, consider professional diecast car painting services.