The Importance of Diecast Restoration UK

Diecast model cars are more than just toys; they are miniature representations of automotive history, cherished collectibles, and investments that can appreciate over time. In the UK, the passion for these detailed models is strong, with a dedicated community of collectors and enthusiasts who appreciate the craftsmanship and history behind each piece. Diecast restoration in the UK is therefore vital. It ensures that these models are preserved for future generations, maintaining their value and allowing enthusiasts to enjoy the beauty and nostalgia they offer. The UK’s rich automotive heritage further fuels this passion, with many models representing iconic British cars and historical events. Restoring these models is not just about fixing damage; it’s about bringing history back to life, ensuring these miniature marvels continue to fascinate and inspire.

Why Restore Diecast Models

Restoring diecast models is a rewarding endeavor for several reasons. Firstly, it breathes new life into a treasured item, transforming a damaged or worn model into a stunning display piece. This can be especially satisfying for models with sentimental value, such as those passed down through families or representing significant events. Secondly, restoration can significantly increase the value of a model, making it a worthwhile investment. A well-restored model can fetch a higher price in the collector’s market, especially for rare or sought-after items. Thirdly, the restoration process itself is a therapeutic and engaging hobby. It allows enthusiasts to develop new skills, from detailed painting and repair work to careful disassembly and reassembly. Finally, restoring diecast models connects enthusiasts with a vibrant community of collectors and restorers, fostering a shared appreciation for these miniature works of art. Diecast restoration is a fulfilling pursuit that combines craftsmanship, historical appreciation, and the joy of bringing beauty back to life.

Benefits of Diecast Restoration

The benefits of diecast restoration are numerous, extending beyond mere cosmetic improvements. Firstly, it preserves the historical and cultural significance of the models. Many diecast cars represent vehicles that are no longer in production or are significant for their historical importance. Restoration ensures these models are maintained for future generations, allowing enthusiasts to appreciate their place in automotive history. Secondly, restoration protects the investment value of the model. Properly restored models are more valuable in the collector’s market, making it a sound investment for enthusiasts. Thirdly, it enhances the aesthetic appeal of the models. Restoration can remove damage, scratches, and wear, returning the model to its original, pristine condition, and making it a centerpiece of any collection. Finally, restoration allows enthusiasts to personalize and customize their models. From choosing paint colors to adding custom details, enthusiasts can create a unique model that reflects their individual style and preferences. Diecast restoration offers both tangible and intangible benefits, including financial gain, historical preservation, and personal satisfaction.

Top 7 Diecast Restoration UK Tips

Restoring diecast models requires patience, precision, and a systematic approach. The following 7 tips will guide you through the process, helping you achieve professional-quality results. Whether you’re a seasoned collector or a beginner, these tips will provide valuable insights and techniques to successfully restore your diecast models in the UK, ensuring they retain their value and beauty for years to come. From assessing damage to seeking professional help, these tips cover the essential steps needed for a successful restoration project. By following these guidelines, enthusiasts can navigate the restoration process with confidence, transforming their damaged models into stunning, museum-quality pieces.

Tip 1 Assessing the Damage

Before starting any restoration project, a thorough assessment of the damage is crucial. This initial step helps determine the scope of work, the necessary tools and materials, and whether professional assistance is required. Start by carefully examining the model under good lighting, noting all imperfections such as scratches, dents, rust, and missing parts. Identify any areas that require special attention, such as intricate detailing or fragile components. Take detailed photographs before starting the work; these images will serve as a reference throughout the restoration process. Documenting the damage allows you to create a plan for the restoration, preventing potential problems and ensuring the final result meets your expectations. This detailed assessment is the cornerstone of a successful restoration project, providing a clear roadmap and a benchmark for evaluating your progress.

Identify the Issues

Identifying the specific issues is key to developing an effective restoration strategy. Focus on pinpointing the exact nature of each imperfection. Are the scratches superficial, or do they penetrate the paint? Is the rust surface-level or has it compromised the metal? Are there missing parts, and if so, can they be sourced or fabricated? Understanding the nature of each issue will determine the appropriate repair techniques. For example, minor scratches can often be buffed out, while deeper scratches may require repainting. Rust may require chemical treatment or abrasive cleaning. Missing parts may necessitate sourcing replacements or creating custom components. By carefully identifying the issues, you will be able to develop a detailed plan for repair, ensuring that each issue is addressed with precision and care, and helping achieve the best possible restoration outcomes.

Evaluate the Scope

After identifying the issues, evaluate the overall scope of the restoration project. Consider the extent of the damage and the complexity of the repairs. Are the repairs confined to a few minor issues, or does the model require extensive work? This assessment will help you estimate the time and resources required for the project. Determine whether you have the necessary tools, materials, and skills to complete the restoration, or if you may need to outsource some tasks. A realistic assessment of the scope will prevent you from taking on more than you can handle and will ensure a successful outcome. It also allows you to set realistic expectations and to plan your project effectively, ensuring you can manage your time and resources efficiently. By evaluating the scope, you can make informed decisions about the best course of action for your restoration project.

Tip 2 Gathering the Right Tools

Having the right tools is essential for a successful diecast restoration. A well-equipped workspace allows you to work efficiently and achieve high-quality results. The specific tools you need will depend on the scope of the restoration, but there are some essential items that every restorer should have. From basic hand tools to specialized equipment, having the right tools makes the restoration process smoother, more accurate, and more enjoyable, helping you transform your diecast models into stunning collectibles. Investing in quality tools will pay off in the long run, enabling you to tackle a wide range of restoration tasks and achieving the best possible results in your diecast restoration projects.

Essential Tools for Restoration

Essential tools for diecast restoration include a variety of hand tools, such as screwdrivers (various sizes and types), pliers (needle-nose, flat-nose, and cutting), and tweezers. You will also need a hobby knife, a set of files (various shapes and grits), and sandpaper (various grits). For cleaning, a soft brush, cotton swabs, and cleaning solvents are useful. A magnifying glass or a head-worn magnifier can be invaluable for detailed work. A small vise is useful for holding parts securely during repairs. For painting, an airbrush or spray cans, masking tape, and paint thinner are essential. These tools will help you handle the meticulous work involved in restoring a diecast model, helping you address a variety of issues such as disassembly, cleaning, body repair, and painting. Having these essential tools on hand ensures you’re well-prepared to handle any restoration project.

Recommended Materials and Supplies

Along with tools, a range of materials and supplies are needed for diecast restoration. These include paint (enamel, acrylic, or lacquer), primer, and clear coat, ensuring a durable and attractive finish. For body repairs, you will need filler (putty or epoxy) and sanding materials. For cleaning, use gentle solvents like isopropyl alcohol, specialized model cleaners, and a range of soft cloths or brushes. For detailing, model glue, decals, and small detail parts are often necessary. Safety equipment, such as gloves and a respirator, should be considered. The appropriate materials and supplies ensure that you can effectively tackle the various stages of restoration, from preparing the surface to applying paint and adding the finishing touches.

Tip 3 Disassembly and Cleaning

Disassembly and cleaning are crucial steps in the diecast restoration process. Careful disassembly allows access to all parts of the model, enabling a thorough inspection and repair. Cleaning removes dirt, grease, and old paint, preparing the surfaces for restoration. These two processes often go hand in hand, as cleaning is often performed during and after disassembly. Proper disassembly and cleaning is essential for laying the foundation for a successful restoration, ensuring the model is in its best possible condition before starting repairs and painting.

Careful Disassembly Techniques

When disassembling a diecast model, it is important to proceed with care and patience. Start by documenting the model’s original condition with photographs. Use the correct tools, such as small screwdrivers and pliers, to remove screws, clips, and other fasteners. Work slowly and carefully, noting the order in which parts are removed, and keeping screws and small parts organized. If any parts are difficult to remove, apply penetrating oil or gentle heat to loosen them. Avoid forcing any parts, as this can cause damage. Disassembly of complex models may require referring to online guides or model schematics. The objective is to separate all the parts without damaging them. This methodical approach makes reassembly much easier and ensures that all areas of the model are accessible for cleaning and repair.

Effective Cleaning Methods

After disassembly, thoroughly clean all parts of the model. Remove old paint, dirt, and grease, preparing the surfaces for the repair and painting process. Begin by washing parts with mild soap and warm water, followed by rinsing and drying them thoroughly. For tougher dirt, use specialized model cleaners or gentle solvents, such as isopropyl alcohol. Use a soft brush or cotton swabs to clean hard-to-reach areas, such as crevices and detail lines. For removing old paint, you may use a paint stripper or carefully sand the surface. Be sure to avoid using harsh chemicals or abrasive cleaning methods. After cleaning, inspect each part for damage or imperfections, which should be addressed before painting. A clean model is essential for achieving a high-quality, professional restoration.

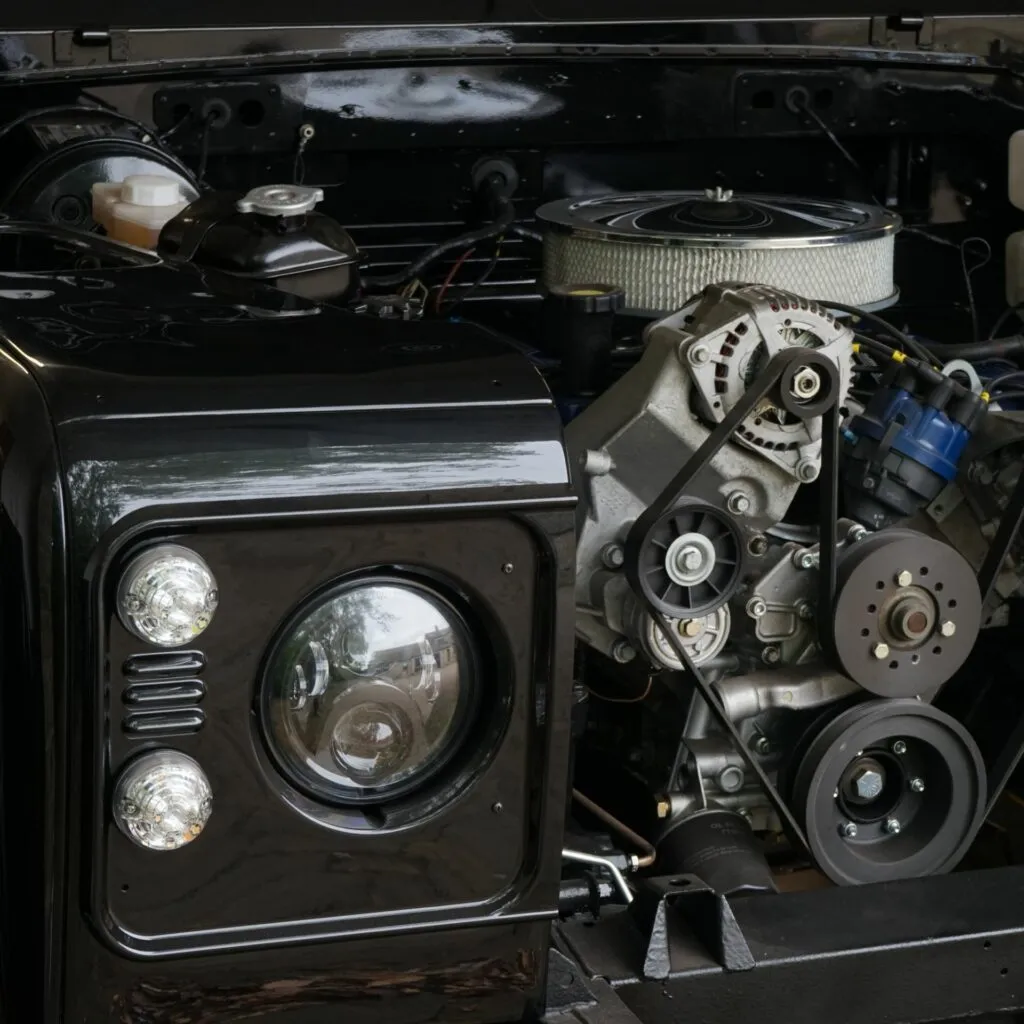

Tip 4 Repairing the Body

Body repair is a critical stage in diecast restoration, focusing on restoring the physical integrity and appearance of the model. This involves addressing dents, scratches, rust, and other imperfections on the metal body. Body repair requires a combination of techniques, including filling, smoothing, and sanding, to restore the original shape and surface of the model. The goal is to create a smooth and flawless surface, providing a perfect base for painting and finishing, and ensuring the restored model looks as good as new. Meticulous bodywork can significantly improve the overall look of a diecast model, and can transform a damaged piece into a stunning collectible.

Dealing with Dents and Scratches

Dents and scratches are common problems in diecast models, and require different approaches. For minor scratches, you may be able to carefully polish the surface using fine-grit sandpaper or polishing compounds. For dents, you may need to carefully manipulate the metal back into its original shape. Small dents can sometimes be pushed out from the inside. More extensive damage may require the use of body filler, such as putty or epoxy, to rebuild the damaged area. When working with dents and scratches, proceed with patience and precision. Avoid using excessive force, which could cause further damage. The goal is to restore the original shape of the model, ensuring a smooth, flawless surface that is ready for painting. Careful handling and precise techniques will result in a significant improvement in the appearance of your restored model.

Filling and Smoothing Imperfections

After repairing dents and scratches, the next step is filling and smoothing any remaining imperfections. Apply a thin layer of body filler over the damaged area, following the manufacturer’s instructions. Use a flexible tool to apply the filler smoothly, ensuring it adheres well to the surface. Allow the filler to cure completely, then sand it down to the original surface contour, using progressively finer grits of sandpaper. Continue sanding until the filled area blends seamlessly with the surrounding surface. Use a guide coat (a light spray of contrasting color) to reveal any remaining imperfections. Once you are satisfied with the smoothness, remove the guide coat. This process creates a flawless base for painting, ensuring a professional finish and enhancing the overall appearance of your diecast model.

Tip 5 Painting and Finishing

Painting and finishing are key steps in diecast restoration. This phase involves selecting the right paint, applying it evenly, and achieving a durable and aesthetically pleasing finish. The quality of the paint job can significantly impact the overall appearance of the restored model. From choosing the right paint to mastering application techniques, these steps are essential for bringing the model to its final, polished form. With the proper techniques and materials, you can create a finish that is both beautiful and long-lasting, restoring your diecast model to its original glory, and ensuring it becomes a prized piece of your collection.

Choosing the Right Paint

Choosing the right paint is essential. Model paints are available in various types, including enamel, acrylic, and lacquer. Enamel paints are durable but take longer to dry. Acrylic paints dry quickly and are easy to clean up, while lacquer paints offer a high-gloss finish but can be more challenging to work with. Consider the original paint type of the model and choose a paint that is compatible with it. Match the color accurately by consulting color charts or using a color-matching tool. Always test the paint on a small, inconspicuous area before applying it to the entire model. Ensure you have the appropriate thinner and other necessary materials for your chosen paint type, and consider the environment where you will be painting, ensuring good ventilation and protection from dust and debris.

Application Techniques

Proper application techniques are essential for achieving a professional-quality paint job. Start by priming the model to provide a smooth surface for the paint to adhere to. Apply thin, even coats of paint, allowing each coat to dry completely before applying the next. Using an airbrush is recommended for achieving a smooth finish, but spray cans can also work well with careful technique. Hold the airbrush or spray can at a consistent distance from the model and move it steadily to avoid runs and drips. Apply multiple thin coats rather than a single thick coat. Once the paint is completely dry, you may need to wet-sand the surface lightly to remove any imperfections. Finish with a clear coat to protect the paint and add shine. Proper application techniques will result in a professional-looking finish that enhances the beauty and value of your restored model.

Tip 6 Detailing and Reassembly

Detailing and reassembly are the final steps in diecast restoration, bringing together all the work that has been done. Detailing involves adding intricate features, such as decals, chrome trim, and other small parts that enhance the model’s realism. Reassembly involves carefully putting the model back together, ensuring that all parts fit correctly and function as intended. This stage brings together all the elements, making the model whole and showcasing your restoration efforts. The attention to detail and the meticulous reassembly are critical to creating a stunning, fully restored diecast model, and a testament to the time, effort, and skill that have gone into the project.

Adding Details and Decals

Adding details and decals brings the model to life. Decals often replicate the original markings, badges, and logos of the real car. Carefully apply decals, using decal setting solutions to ensure they adhere properly to the surface. For added realism, consider adding small details such as chrome trim, window glass, and other features. Use fine-tipped brushes and model paints to add details such as trim, lights, and other small components. Take your time, work carefully, and use reference photos of the original model. The details will really bring the model to life and provide that level of realism which is so important in the diecast world.

Careful Reassembly

Reassembly is the final step, and it is important to proceed carefully. Refer back to photographs taken during disassembly to ensure all parts are placed correctly. Ensure all parts align and fit as they should. Use the correct tools for reassembly, such as small screwdrivers and pliers. Tighten screws carefully to avoid stripping threads or damaging parts. Check that all moving parts, such as doors and wheels, function correctly. After reassembly, carefully inspect the model for any imperfections or issues. Carefully reassembling your diecast model is the final step of bringing a beautiful collectible back to life, and making your restoration project a success.

Tip 7 Seeking Professional Help

While many enthusiasts enjoy restoring diecast models as a hobby, there are times when seeking professional help is the best option. Complex restoration projects, models with extensive damage, or those with high value may require specialized skills and equipment. For models with high sentimental or financial value, the expertise of a professional restorer can ensure the best possible outcome. Knowing when to seek professional help can prevent costly mistakes and protect the value of your model. In the UK, there is a network of professional restorers who specialize in this area, offering expertise and resources that can be invaluable for more complex projects.

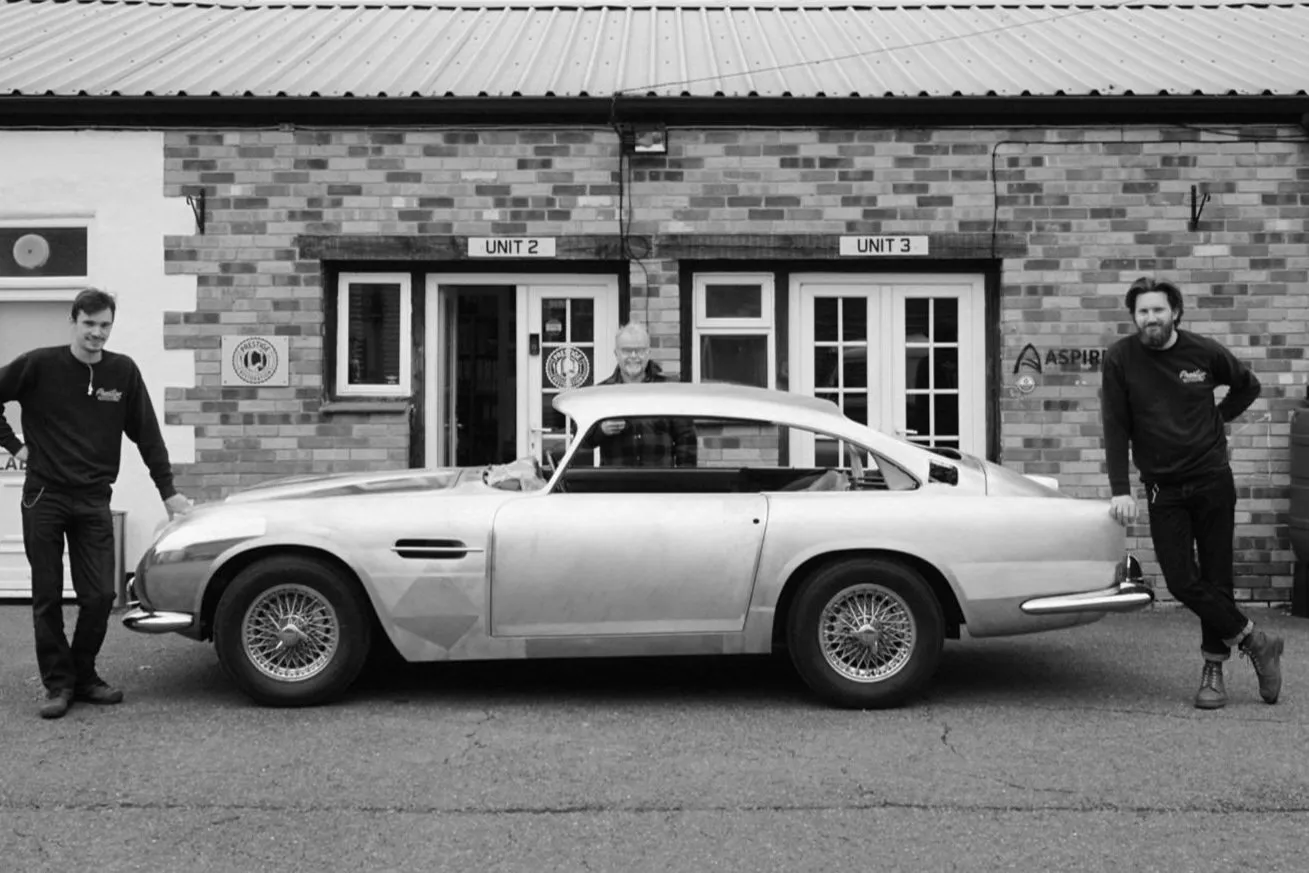

When to Consider Professional Services

Consider professional help when faced with complex or extensive damage. If the model has significant rust, missing parts, or requires intricate repairs, the skills and equipment of a professional restorer can prove invaluable. Also, consider professional services if you lack the necessary experience, tools, or time. Restorers have access to specialized tools, materials, and techniques that may be difficult for hobbyists to obtain. If the model is rare or of significant value, professional restoration can protect its investment. They have the knowledge and resources to ensure the model is restored to its original condition, maintaining and potentially increasing its value. Ultimately, the decision depends on the extent of the damage, your own skills and resources, and the value of the model.

Finding a Reliable Restorer

Finding a reliable restorer is essential for a successful project. Start by researching restorers in the UK who specialize in diecast models. Look for restorers with a strong reputation and a portfolio of past work, providing examples of their skill and the quality of their work. Check online reviews and testimonials from previous clients to gauge their experience and customer satisfaction. Inquire about their experience with similar models, their pricing, and their turnaround time. Request a detailed quote and discuss your expectations clearly. Visit the restorer’s workshop, if possible, to assess the quality of their equipment and work environment. Choose a restorer who is passionate about their work, communicates effectively, and understands your needs. By carefully selecting a reliable restorer, you can ensure that your valuable diecast model receives the best possible care and restoration, preserving its beauty and value for years to come.

Conclusion

Diecast restoration in the UK is a rewarding hobby, allowing enthusiasts to preserve and celebrate the history and beauty of miniature model cars. From assessing damage to seeking professional help, each step of the restoration process requires care, patience, and attention to detail. By following the 7 tips outlined in this guide, enthusiasts can successfully restore their diecast models, transforming them from damaged or worn items into stunning collectibles. Whether you are a seasoned collector or a beginner, the skills and knowledge gained during the restoration process add to the enjoyment of owning and preserving these unique pieces. The satisfaction of bringing a cherished model back to life is a rewarding experience. Embrace the journey, and enjoy the process of restoring these miniature works of art. Happy restoring!