What is Diecast and Pressing PTY LTD?

Diecast and Pressing PTY LTD is a manufacturing company specializing in two primary processes diecasting and metal pressing. These techniques are vital in producing high-quality components for a wide range of industries. The company leverages advanced technologies and a commitment to precision to deliver reliable and durable products. With a focus on efficiency and customer satisfaction, Diecast and Pressing PTY LTD serves as a crucial partner for businesses requiring precision-engineered metal parts. The company’s expertise lies in transforming raw materials into complex shapes with tight tolerances, ensuring products meet the demanding requirements of modern applications. This involves a deep understanding of materials, processes, and quality control.

The Core Services Offered

Diecast and Pressing PTY LTD provides comprehensive manufacturing solutions centered on diecasting and metal pressing. These services are meticulously designed to meet the diverse needs of its clientele. The company excels in producing high volumes of complex, net-shape parts, minimizing material waste and reducing production costs. Its expertise includes design assistance, prototyping, and full-scale production, ensuring that each project is handled with precision and care. Furthermore, the company employs state-of-the-art equipment and skilled technicians to deliver high-quality results consistently. This commitment to quality and efficiency has solidified Diecast and Pressing PTY LTD’s position as a trusted manufacturer for various industries, making it a key player in the supply chain.

Diecasting Explained

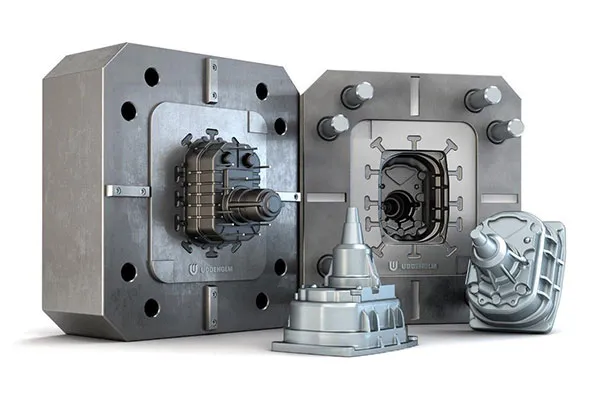

Diecasting is a manufacturing process where molten metal is injected into a mold under high pressure. This technique is used to create intricate and complex metal parts with remarkable precision. The process involves creating a mold, often from steel, which can withstand extreme temperatures and pressures. The molten metal, typically aluminum, zinc, or magnesium alloys, is then forced into the mold cavity, filling it completely. Once the metal solidifies, the mold is opened, and the part is ejected. Diecasting is highly efficient, allowing for rapid production of large quantities of parts with excellent dimensional accuracy. The resulting components are known for their strength, durability, and smooth surface finish, making them ideal for various applications. Diecasting is particularly well-suited for producing parts with intricate designs, thin walls, and complex geometries.

Pressing Explained

Metal pressing, also known as stamping, involves shaping metal sheets or coils into desired forms using dies and presses. This process is commonly used to create a wide array of parts, from simple brackets to complex automotive body panels. The metal sheet is placed between the dies, and a press applies significant force to shape the metal. Pressing can be used for various operations such as blanking, bending, drawing, and coining. The efficiency of metal pressing allows for the mass production of parts at high speeds. The tooling and machinery used in metal pressing must be precisely engineered to ensure accuracy and consistency. The choice of metal and the specific pressing process are determined by the required part characteristics and the intended application. Metal pressing is a versatile and cost-effective method for producing a wide range of metal components.

The Advantages of Using Diecast and Pressing PTY LTD

Superior Quality and Precision

Diecast and Pressing PTY LTD is dedicated to maintaining the highest standards of quality and precision in all its manufacturing processes. The company’s commitment to quality control begins with meticulous material selection and extends through the entire production cycle. Advanced technologies and rigorous testing methods are employed to ensure each part meets or exceeds industry standards. State-of-the-art equipment and skilled technicians contribute to the production of components with exceptional dimensional accuracy and surface finishes. The precision offered by Diecast and Pressing PTY LTD minimizes the need for post-processing and assembly adjustments, leading to significant cost savings and enhanced product reliability. Their dedication to quality has earned them a reputation for excellence.

Cost-Effectiveness

One of the key advantages of utilizing Diecast and Pressing PTY LTD is the cost-effectiveness of its services. Through efficient processes, optimized material usage, and economies of scale, the company helps clients reduce their manufacturing costs. The high-volume production capabilities and streamlined workflows contribute to lower per-unit expenses. Moreover, the precision offered by diecasting and pressing minimizes waste and reduces the need for rework, further enhancing cost savings. Diecast and Pressing PTY LTD offers competitive pricing and value-added services to ensure clients receive the best return on their investment. The overall cost-effectiveness makes the company an attractive option for businesses looking to optimize their manufacturing operations without compromising quality.

Design Flexibility

Diecast and Pressing PTY LTD provides exceptional design flexibility, allowing clients to bring complex and innovative product designs to life. Their advanced manufacturing techniques can accommodate intricate geometries and tight tolerances, which enables the creation of parts with unique shapes and features. The company’s engineering team works closely with clients to optimize designs for manufacturability, providing valuable insights and suggestions. This collaborative approach ensures that the final product meets the required specifications while maximizing efficiency and minimizing production costs. The ability to create complex designs makes Diecast and Pressing PTY LTD a valuable partner for clients across multiple industries. This flexibility allows businesses to push boundaries with their product designs, leading to new innovations and improvements.

The Industries Served by Diecast and Pressing PTY LTD

Automotive

The automotive industry is a significant consumer of diecast and pressed parts. Diecast and Pressing PTY LTD provides components for various automotive applications, including engine parts, transmission components, and structural elements. The company’s ability to produce high-strength, lightweight parts is critical for improving fuel efficiency and vehicle performance. With the automotive sector constantly evolving, Diecast and Pressing PTY LTD keeps up with the latest industry trends to meet their client needs. Their ability to provide parts with tight tolerances and complex geometries is critical. These parts are used in everything from engine blocks to interior components, highlighting the versatility of the company’s offerings.

Aerospace

The aerospace industry has extremely stringent requirements for its components, making Diecast and Pressing PTY LTD a valuable supplier. Their processes meet aerospace standards and produce parts essential for aircraft and spacecraft, including structural components and engine parts. The company’s precision and attention to detail are essential in ensuring safety and reliability in the aerospace sector. The durability and lightweight nature of the parts are critical for flight efficiency. Diecast and Pressing PTY LTD is committed to providing parts that meet the rigorous demands of the aerospace industry, helping clients meet strict standards. The ability to produce complex geometries and tight tolerances ensures the reliability of aerospace systems.

Consumer Electronics

Diecast and Pressing PTY LTD also serves the consumer electronics industry, producing parts for devices such as smartphones, laptops, and other electronic gadgets. The company’s capabilities include producing small, complex components with high precision, meeting the industry’s demands for miniaturization and quality. The demand for sleek designs and durable parts makes diecasting and pressing ideal manufacturing methods. Diecast and Pressing PTY LTD has specialized in producing parts that are both visually appealing and functionally effective. Their ability to work with various materials and finishes enhances the aesthetic appeal of consumer electronics. By providing high-quality components, Diecast and Pressing PTY LTD contributes to the innovation and advancement of consumer electronics.

The Diecasting and Pressing Process

Design and Tooling

The design and tooling phase is crucial for both diecasting and pressing. In diecasting, this involves the creation of a mold or die, which is precision-engineered to match the part’s design. The molds are typically made of high-strength steel to withstand the high temperatures and pressures involved in the process. In metal pressing, the tooling involves designing dies and press setups, which determine the shape and form of the final product. The design process takes into consideration the required part specifications, materials, and manufacturing efficiencies. Diecast and Pressing PTY LTD uses advanced CAD/CAM software and skilled toolmakers to create highly accurate and efficient tooling. This ensures that the molds and dies meet the required specifications, leading to high-quality parts and cost-effective manufacturing.

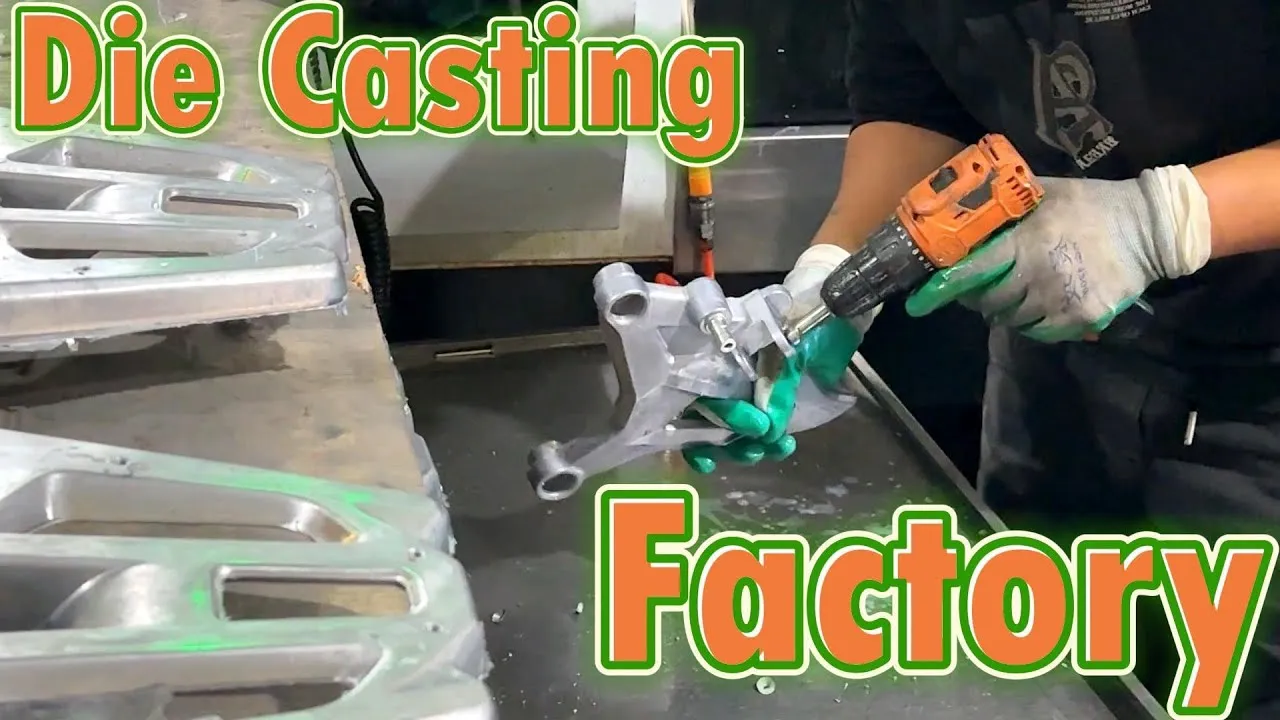

Diecasting Process

The diecasting process involves injecting molten metal under high pressure into the mold. Once the mold is ready, the molten metal is injected into it. This rapid filling process ensures that even intricate details are captured with precision. The metal then solidifies within the mold cavity. After solidification, the mold is opened, and the part is ejected. Diecasting is suitable for high-volume production. Diecast and Pressing PTY LTD carefully controls the process parameters, such as temperature, pressure, and cooling time, to ensure the parts meet the required specifications. Post-processing may be performed to remove any excess material, and the parts are then inspected for quality and accuracy. The process enables the production of complex shapes, thin walls, and fine details efficiently and at scale. The process is optimized to minimize waste and maximize output.

Pressing Process

The pressing process begins with the placement of a metal sheet or coil between dies. These dies are precision-engineered tools designed to shape the metal into the desired form. The press applies high force to the metal, causing it to deform and take on the shape of the dies. Various pressing operations, such as blanking, bending, drawing, and coining, may be performed depending on the complexity of the part. Blanking involves cutting the metal, bending modifies the shape, drawing stretches the metal into a deeper form, and coining creates intricate details. Once the pressing operation is complete, the part is removed from the dies and can undergo additional finishing processes. The company uses sophisticated presses to execute these procedures with precision and consistency, ensuring each part is within required tolerances. This method offers versatility and efficiency in manufacturing a wide range of metal components.

Quality Control and Assurance

Inspection and Testing

Quality control is an integral part of the manufacturing process at Diecast and Pressing PTY LTD. Inspection and testing procedures are performed at various stages to ensure that each part meets the required specifications. These include dimensional checks, visual inspections, and functional tests. Advanced metrology equipment, such as CMMs (Coordinate Measuring Machines), is used to measure parts accurately. Furthermore, the company uses non-destructive testing methods, such as X-ray and ultrasonic testing, to detect any internal defects. The company’s commitment to inspection and testing guarantees the production of high-quality parts with consistent performance. These rigorous inspection and testing procedures are in place to detect any defects and ensure that only high-quality parts are delivered to customers. This stringent approach is a key element of the company’s quality assurance process.

Certifications and Standards

Diecast and Pressing PTY LTD adheres to the highest industry standards and certifications to demonstrate its commitment to quality and reliability. The company likely holds certifications such as ISO 9001. These certifications validate that the company’s quality management system is effective and ensures consistent manufacturing processes. The company also follows specific industry standards depending on the sectors it serves, such as IATF 16949 for the automotive industry and AS9100 for aerospace. By meeting these standards, Diecast and Pressing PTY LTD provides customers with confidence that their parts are manufactured to the highest quality. These certifications and standards are essential for ensuring that the company’s processes meet or exceed industry requirements and client expectations.

Future Trends in Diecast and Pressing

Sustainability in Manufacturing

Sustainability is becoming an increasingly important factor in the manufacturing industry. Diecast and Pressing PTY LTD is adapting to these trends by incorporating eco-friendly practices. This includes utilizing recyclable materials, optimizing processes to reduce waste, and implementing energy-efficient technologies. Investing in sustainable practices shows a commitment to reducing the environmental impact of the manufacturing. The use of sustainable materials also enhances the appeal of products and aligns with customer preferences. The company aims to minimize its carbon footprint through its manufacturing processes. It recognizes that adopting sustainable practices is not only environmentally responsible but also a business advantage. This focus on environmental responsibility enhances the company’s brand image.

Technological Advancements

Technological advancements continue to reshape the diecast and pressing industry. Diecast and Pressing PTY LTD stays at the forefront of innovation. Advanced technologies include automation, AI-powered quality control systems, and additive manufacturing. Automation enables higher production volumes and reduces labor costs. AI-powered systems enhance quality control and minimize defects. By embracing these new technologies, Diecast and Pressing PTY LTD aims to boost efficiency, quality, and design capabilities. These advancements allow for greater precision, faster production cycles, and the creation of innovative products. Their focus on technology ensures a competitive edge and the ability to meet the future challenges. Continued investment in research and development is integral to maintaining its leadership position.

Choosing Diecast and Pressing PTY LTD

Factors to Consider

When choosing a diecast and pressing supplier, several factors should be considered. The most important is the supplier’s experience and expertise in the industry. Evaluate the quality and precision standards. Look for certifications and a history of meeting industry requirements. Consider the supplier’s capacity and ability to manage your project’s scale. Assess the technology and equipment used to assess their suitability. Evaluate the supplier’s flexibility and ability to accommodate design changes. Look into the company’s customer service. By taking all of these factors into account, you can choose a manufacturing partner that provides high-quality parts. Consider lead times and delivery schedules and determine whether they align with your project needs. Ensure that the supplier has a proven track record of on-time delivery and project success.

Contact Information

For inquiries or to discuss a project, contact Diecast and Pressing PTY LTD. Visit their website or contact them via phone or email. The team is available to provide detailed information and tailored solutions. Their professional staff will offer assistance, from design consultation to production planning. Contact information is readily available on their website, or through a quick search. Diecast and Pressing PTY LTD welcomes the opportunity to discuss your manufacturing needs and provide the support needed for your project. Reach out for personalized service and expert advice for your diecasting or metal pressing needs. Their team is always ready to provide prompt and professional responses.