What is a Custom Diecast Model?

A custom diecast model is a meticulously crafted miniature replica of a real-life car, specifically designed and created to your exact specifications. Unlike mass-produced models, custom diecast models offer a unique opportunity to own a personalized miniature of your vehicle, a cherished classic, or even a dream car that you’ve always admired. These models are typically made from diecast metal, which provides weight and durability, and are often combined with plastic and other materials for detailing. The level of customization can range from simple color changes to highly detailed replicas, including interior features, engine components, and realistic paint finishes. Owning a custom diecast model is more than just collecting; it’s about preserving a piece of automotive history, celebrating personal milestones, and expressing individuality. They are treasures for car enthusiasts.

Why Create a Custom Diecast Model?

There are numerous compelling reasons to commission a custom diecast model. For many, it’s a way to immortalize a specific car, such as a first car, a family heirloom, or a vehicle that holds sentimental value. The ability to replicate your own car allows you to have a tangible representation of your vehicle, perfect in every detail, to cherish for years. Custom models also serve as exceptional gifts for car enthusiasts, offering a personalized and thoughtful present that showcases a shared passion. Furthermore, they can be a fantastic investment, as highly detailed and well-executed custom models can appreciate in value over time, especially if they represent a rare or unique vehicle. Whether you’re seeking a unique collectible, a personalized keepsake, or a way to celebrate your love for cars, a custom diecast model offers an unparalleled opportunity to fulfill these desires.

Benefits of Owning a Custom Diecast Model

The advantages of owning a custom diecast model extend beyond mere aesthetics. Firstly, they are highly collectible items, and owning a custom-made model significantly enhances the uniqueness of your collection. Secondly, they offer an exceptional level of detail, often surpassing the quality of mass-produced models, as model makers devote significant time to replicating every aspect of the car with precision. Thirdly, custom diecast models make for unique gifts that show thought and consideration. A model of a car a person loves can bring a lot of happiness. Lastly, they offer the opportunity to preserve a piece of automotive history, allowing you to own a scale replica of a car that might be otherwise unattainable or difficult to find. These models become a timeless reminder of a car and the good times.

The Process of Creating a Custom Diecast Model

Creating a custom diecast model involves a detailed and collaborative process. It typically begins with choosing a model maker and providing them with your car’s specifications. The model maker will then create a 3D design for your approval, and once you’re satisfied, the model goes into production. This process requires careful consideration and attention to detail to ensure the final product accurately reflects your vision. Understanding each step is key to a smooth and successful project. There are many details that go into creating these models, which means you need to be prepared. Choosing the right model maker is crucial to the entire process. There are many model makers with various specialties, so find one who can provide the services you need.

Choosing a Model Maker

The selection of a model maker is the most pivotal step in the process. The quality of the final product hinges on the model maker’s expertise, experience, and attention to detail. It’s crucial to find a maker who specializes in the type of car you want to replicate, whether it’s a classic, a modern sports car, or something else entirely. Research their portfolio thoroughly, examining the quality of their previous work. Pay close attention to the level of detail, the accuracy of the proportions, and the overall finish. Read reviews and testimonials from previous clients to gauge their reliability, communication skills, and ability to deliver on time. Consider factors like pricing, turnaround time, and the materials they use. A good model maker will be responsive to your needs and willing to collaborate to ensure the final model meets your expectations.

Researching Model Makers

Begin your search by exploring online platforms, social media, and dedicated forums for model car enthusiasts. These spaces often feature recommendations and reviews of model makers. Search for specialists in custom diecast models, and review their websites and portfolios. Check for customer testimonials or case studies demonstrating their experience and the quality of their output. Websites like Etsy and specialized model car forums can provide a wealth of information. Look for makers with a proven track record of delivering high-quality models and with positive feedback from past customers. Compare the services offered, the materials used, and the pricing to find a model maker that aligns with your requirements and budget. Read all reviews from customers before contacting the model maker.

Evaluating Model Maker’s Portfolio

Once you’ve identified potential model makers, thoroughly review their portfolios. Pay close attention to the detail and accuracy of the models they have created. Look for realistic paint finishes, precisely replicated interior details, and accurate proportions. Assess the craftsmanship of the models. Consider the scale and the type of cars they specialize in. Does the model maker have a portfolio showing expertise with the make and model of your vehicle? Examine the overall finish, looking for any imperfections or inconsistencies. Check for realistic engine details and other intricate components. Look for models that reflect the attention to detail you expect. The portfolio gives you a strong indication of the quality of work you can expect. You can use the portfolio to assess the model maker’s style and experience.

Providing Your Car Details

Providing comprehensive and accurate information about your car is essential for ensuring the diecast model accurately reflects the real vehicle. The more details you provide, the better the model maker can replicate your car’s unique features. This includes everything from the specific model year and trim level to any modifications or custom features. Prepare to provide all the information requested by the model maker. Open and clear communication is critical throughout the process. Make sure you are always available to answer questions. This process is important to make sure you are getting the model you want. The more details the better.

Essential Information

Begin by providing the make, model, and year of your car. Specify the trim level (e.g., base, Sport, or Limited) and any optional packages. Include the exact color of the exterior paint, including the paint code if available. Note any unique features or modifications. Be clear about the type of wheels and tires. Describe the interior details, including the color of the seats, dashboard, and carpets. Share any specific details about the engine and exhaust system. The more information you can give, the better. Make sure you have all of this information before you reach out to the model maker to save time. Also, consider having this information ready before you even begin looking for model makers.

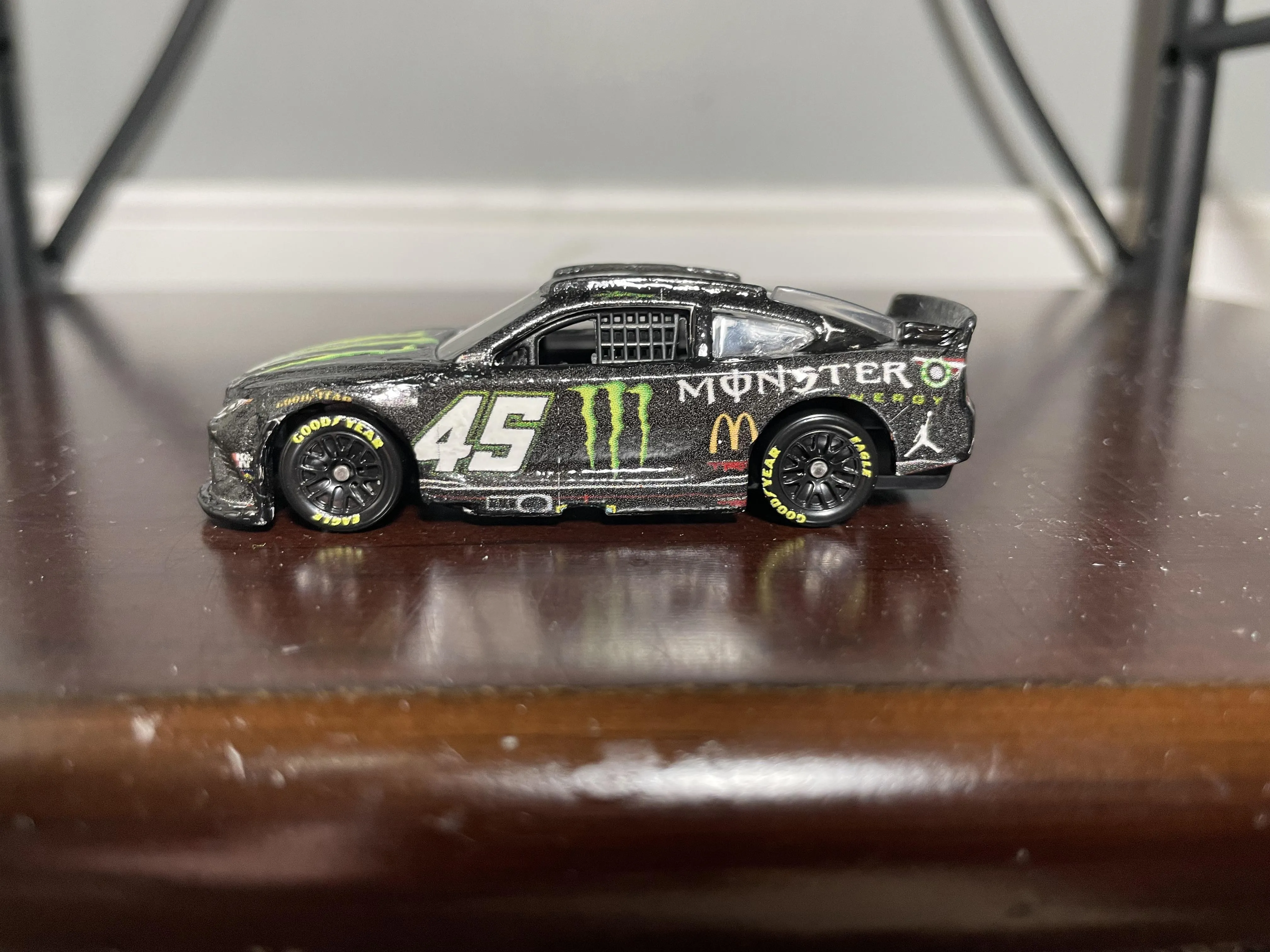

Photographs

High-quality photographs are crucial for accurately recreating your car’s details. Provide a variety of photos taken from different angles, including front, rear, side, top, and interior views. Include close-up shots of unique features, such as emblems, badges, and custom accessories. If you have any modifications, take detailed photos of these as well. If possible, capture the engine bay and the undercarriage of your car. The more reference material you provide, the better the model maker can understand your car’s specifics. Ensure that the photos are clear and well-lit to show the details. If you can’t take pictures of the car, you can also consider using the internet. Websites such as Google Images can provide additional angles and details if you are looking for specific details.

Selecting the Scale

Choosing the correct scale is a critical decision, as it affects the size and overall look of your custom diecast model. Common scales include 1:18, 1:24, and 1:43, each offering a different balance of detail and size. The scale you choose influences the level of detail that can be incorporated and the space required to display your model. The choice depends on your preferences, display space, and budget, as larger scales typically allow for more intricate detailing but also come with a higher price tag. Consider your available display space and the level of detail you desire. Evaluate the dimensions of the model based on the scale and ensure it fits your collection or desired display area. Remember that larger models provide more surface area for detailing.

Common Diecast Model Scales

The most popular scales for diecast models are 1:18, 1:24, and 1:43. A 1:18 scale model is 1/18th the size of the actual car. This scale offers a good balance of detail and size, allowing for intricate features such as opening doors, detailed interiors, and engine components. 1:24 scale models are smaller than 1:18 scale, but they still offer a good level of detail and are suitable for collectors with limited display space. 1:43 scale models are smaller still. This scale is suitable for collectors who want a variety of models in a smaller space. Consider your display area and preferences when choosing the scale. Other scales are available, but these are the most popular. Consider these scales as well when considering the details you want.

Understanding the Scale

Understanding scale is essential for visualizing the size of your custom diecast model. A 1:18 scale model, for example, means that every 1 inch on the model represents 18 inches on the real car. This also means that smaller scales like 1:43, every 1 inch represents 43 inches on the real car. The scale you select dictates the size of the model, the level of detail possible, and the price. Determine the dimensions of your car and calculate the model’s size using the scale ratio. For example, a 1:18 scale model of a car that is 16 feet long will be about 10.6 inches long. Carefully consider the size and detail to choose the scale that fits your needs. Before choosing a scale, you can always look up models of the car you want to see what scale you like best.

Material Selection for Your Model

The choice of materials significantly impacts the look, feel, and durability of your custom diecast model. Diecast metal is the most common material, providing weight and a realistic feel, but other materials such as plastic, resin, and photo-etched parts are also used for different components. Each material offers specific advantages and disadvantages. Ensure you understand the properties of each material and its impact on the overall quality of the model. The choice of materials can affect the level of detail possible and the realism of the model. Quality materials are going to be more expensive. The higher the cost the better the quality will be.

Metal vs Plastic Considerations

Diecast metal is the primary material for the body of most custom models. Metal offers a feeling of quality, and it can support a level of detail. High-quality diecast metal provides a more authentic look and feel. Plastic components, such as interior parts, are often used to offer flexibility and allow for intricate detailing. The use of plastic allows for complex shapes and fine details that would be difficult to achieve with metal. Resin can be used for custom parts or detailing, providing versatility in terms of shape and form. Choose materials that complement each other and enhance the overall quality. Choose components that are going to last a long time and not be damaged. Keep the original car in mind and make sure to match it.

Additional Detailing Options

Beyond the main materials, many detailing options can enhance the realism and appeal of your custom diecast model. These include photo-etched parts for intricate details like grilles and badges, custom decals for logos and markings, and specialized paints and finishes. Consider incorporating opening doors, hoods, and trunks to showcase the interior and engine components. Highly detailed models may even feature working lights or other interactive elements. Discuss these options with your model maker to determine which detailing features can be incorporated into your model and to fit your budget. The right details help to bring your custom diecast model to life. It will be a joy to look at a model that has all the details that matter to you.

The Design and Approval Stage

The design and approval stage is where your vision for your custom diecast model takes shape. The model maker will create a 3D design based on your specifications and reference materials. This initial design is the foundation for the entire project, and it’s important to ensure that every detail is accurate and meets your expectations. Open and consistent communication is key throughout this stage. You can help prevent issues during the production stage by making sure the model is perfect. This is a collaboration between you and the model maker. Be sure to be responsive to all communications.

Reviewing the 3D Design

Once the model maker completes the 3D design, they will provide it to you for review. Examine the design carefully, paying attention to the overall proportions, the accuracy of the details, and the fit and finish of the components. Check every aspect of the model, including the body shape, the wheels, and the interior. Make sure the design correctly represents your car. If the model has opening features, make sure they work as intended. Don’t hesitate to ask questions and request clarifications from the model maker. This is the stage to point out any inconsistencies or areas that need adjustment. Provide clear and concise feedback to the model maker.

Making Revisions

Based on your feedback, the model maker will make revisions to the 3D design. This may involve making adjustments to the body shape, the interior details, or any other features. During this stage, the model maker may provide updates to the design. Provide additional photos or information to improve the model. Communicate your revisions and requirements clearly and concisely. Review the updated design and provide additional feedback until you’re satisfied with the final result. Be patient, as the revision process may take multiple iterations. Ensure that all the adjustments are made correctly before approving the design for production. This is a vital part of the process that will help you get the model you want.

Production and Delivery

Once you approve the final design, the custom diecast model enters the production phase. During this stage, the model maker transforms the digital design into a physical object. The production process varies depending on the model maker, the materials used, and the level of detail. Keep in touch with the model maker. The production stage is a key stage in the creation of your model. The model maker will use the final design and your specifications to create the final product. After the production phase, the model will undergo a quality check to make sure it meets your standards. Then, the model is packaged and shipped to you.

Understanding Production Time

Production time varies based on complexity, detailing, and the model maker’s workload. Highly detailed models may take several months to complete. The production time is generally longer than the design phase. Discuss the estimated production timeline with your model maker. Stay in contact to receive updates. Be patient throughout the production process. The model maker will do their best to create a high-quality product. The complexity and materials used in the model will impact the production time. Production time varies based on the model maker and the car that is being created. Don’t expect the process to be fast. High-quality models take a long time to create. It takes time to create a high-quality product.

Receiving Your Custom Diecast Model

Upon receiving your custom diecast model, carefully inspect it for any damage or defects. Verify that the model accurately reflects your specifications and that all the details are present. Check that all features, such as opening doors or working lights, function correctly. If any issues arise, contact the model maker immediately to discuss possible solutions. Once you’re satisfied with the model, it’s time to display and cherish it. Taking care of the model is essential to keeping it in good condition. The model is now a part of your collection. The model is a representation of your vehicle. You will be proud to display it to your friends and family.

Displaying and Caring for Your Model

Proper display and care will help preserve your custom diecast model for years to come. Choose a display location that protects the model from direct sunlight and extreme temperatures, which can damage the paint and materials. Use a display case or a dust-proof cabinet to shield the model from dust and debris. Handle the model with care, avoiding touching the painted surfaces. Regularly dust the model with a soft cloth or a specialized model-cleaning brush. Avoid using harsh chemicals or abrasive cleaners. The goal is to protect the model from dust and direct sunlight. Keeping the model out of direct sunlight and extreme temperatures will help preserve it. Handle the model with care.

Display Ideas

There are many ways to showcase your custom diecast model. Display cases offer an elegant and practical way to protect your model while allowing you to view it from all angles. You can arrange your models on shelves or in cabinets, grouped by make, model, or scale. Consider creating a themed display that complements your car or collection. Use lighting to highlight the details of your model. This can be done using spotlights or LED strips. You can display models on a desk or in a living room. The goal is to be able to view the models. Get creative and show off your models to your friends and family.

Caring for Your Model

Regular cleaning and maintenance will extend the life of your custom diecast model. Dust the model regularly with a soft cloth or a specialized model-cleaning brush to prevent dust from accumulating. Be gentle when handling the model, and avoid touching the painted surfaces. Store your model in a display case or a dust-proof cabinet. Keep the model away from direct sunlight and extreme temperatures. If any parts of the model become loose or damaged, contact the model maker for repair. Following these tips will ensure that your custom diecast model remains in pristine condition for years to come. With care, the model will last a very long time. Use the proper supplies to maintain your model.